Did you know that heavy-duty trucks account for around 25% of global road emissions? This is while they represent only 1% of total fleet vehicles on the road. (World Economic Forum)

Large parts of the transport sector are moving over to electric powered vehicles. For example, vehicles in public transport, mining and delivery industries are increasingly electrified.

However, long-range, heavy-duty vehicles (HDV’s) for carrying freight are still almost entirely powered by fossil fuels. Their large payloads have so far made the shift to electric impossible. Importantly, these kinds of vehicles make up some two-thirds of the world’s transportation sector.

Currently, global freight accounts for 2.9 gigatons a year in tailpipe CO2 emissions.

In order to decarbonise the sector and impact global emissions, there needs to be much more private and public investment.

This article looks at the currently available technology and policy, to show where the freight industry is heading in 2022.

“The pace of global warming is accelerating and the scale of the impact is devastating. The time for action is limited – we are approaching a tipping point beyond which the opportunity to reverse the damage of CO2 emissions will disappear.”

Eliot Spitzer (US Attorney and politician)

Do We Have Electric Trucks in 2022?

The latest data from the European Automobile Manufacturers Association (ACEA) shows that 97.9% of new trucks registered in the EU still run on diesel.

Further, purely electric trucks account for just 0.2% of new fleet sales.

However, year-on-year, the data is telling. In 2019, demand for electric trucks grew by 109.2%. Also, the electric truck market will climb to USD 57.67 billion by 2027 from USD 22.63 billion in 2021

Nevertheless, sales of electric trucks will need to hit at least 10% of global fleets by 2030. This is vital to meet global emissions reduction targets.

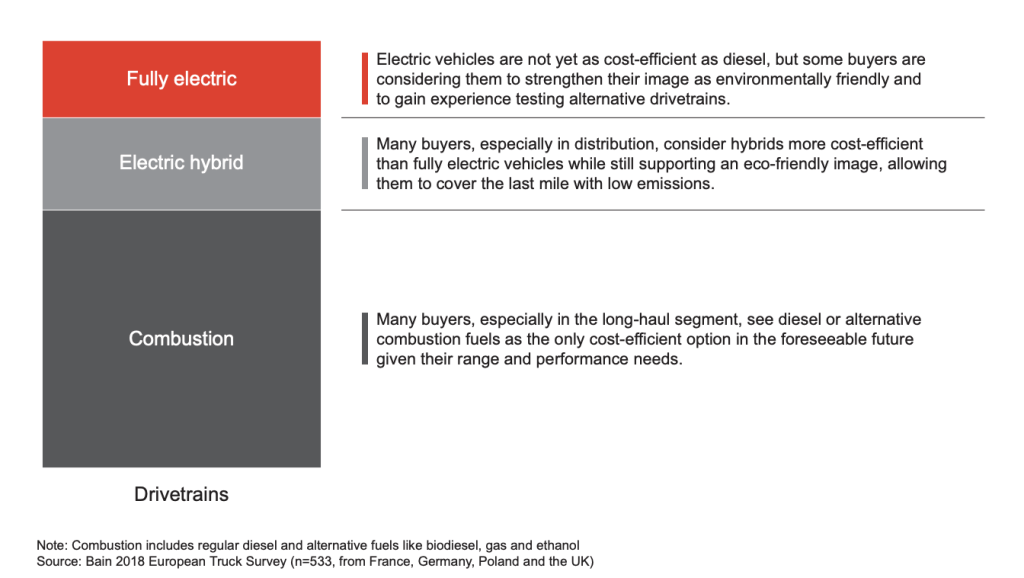

Fortunately, demand remains strong. A survey conducted by Europe’s Bain & Company found that some 40% of respondents were considering buying one or more electric or hybrid trucks with their next purchase. (Weforum)

New prototypes for Low Carbon Transport

Manufacturers are already showcasing prototypes. Still, it will take years before electric trucks become the first choice for fleet buyers. Meanwhile, hybrids or low emission combustion engines are gaining popularity, as shown in the diagram below. (Bain and Company)

This is good news – and helped by the fact that Europe has set ambitious targets to decarbonise. In fact, the European Automobile Manufacturers Association projects around 200,000 electric trucks will be on the road by 2030. (World Economic Forum).

Daimler, the world’s largest truck maker, will sell only zero-emission vehicles by 2039. Also, brands like Volvo Trucks, Renault Trucks and MAN are changing their designs. There are also important new entrants to the market in Tesla and Nikola.

The Problem with Batteries

50-60% of Europe’s freight is transported less than 500 kilometres. Today, battery-powered trucks have a 150-kilometre to 200-kilometre range. That means electric trucks are certainly feasible – if servicing infrastructure is in place. However, their large batteries reduce payloads by up to 15%.

One solution is to change freight regulations and allow for the extra weight created by the batteries. Even so, the arrival of smaller batteries will be a major driver for sales in this kind of vehicle.

Low Carbon Transport vehicles alone will not Reduce Emissions

Firstly, it’s vital to understand exactly what sustainable transport means in practice. According to The Scientific and Technical Advisory Panel: “Sustainable low-carbon transport provides economically viable infrastructure and operation that offers safe and secure access for both persons and goods whilst reducing short and long-term negative impacts on the local and global environments”. (STAP-Sustainable Transport)

Put simply, this means a sustainable transport industry meet demand from all sectors of the population. It must provide full coverage for people and goods transport, even for remote and regional users. In addition, it must reduce its impact on the environment overall. This means more than just the emissions produced by the vehicles.

This, it is simplistic to look at carbon neutral transport separate from the energy industry overall. Certain changes are essential. Let’s look at the most important of these:

1. We need more low carbon sources of power

Firstly, we must reduce or remove carbon dioxide from the power ‘grid’. With batteries, emissions still come from the electricity plant. Right now, the power sector is changing as the cost of renewables decline. As a result, the cost of solar power has fallen by as much as 80 percent, and wind power by about 40 percent. Altogether, renewables for energy production are becoming more competitive with fossil fuels. (McKinsey and Company)

Other technologies include:

- The use of Biofuels in vehicles. Biofuels come from organic matter and include a wide range of materials. Importantly, biofuels create less harmful carbon emissions than standard diesel. However, they’re expensive and limited in supply.

- Bioenergy carbon capture and storage (BECCS). Once again, this is a process in which plant matter is burned to generate heat and electricity. On a large scale, this involves capturing any CO2 emissions before it enters the atmosphere. However, it is not clear to what extent the burning of ‘biomass’ can be scaled up. The technology is still relatively new.

- Carbon capture, use, and storage (CCUS), where CO2 emissions from burning fossil fuels is captured. Captured CO2 can be re-used, or stored underground. CCUS has been shown to work in principle. However, it remains expensive.

- Power to gas to power (P2G2P), which involves using excess electricity to produce hydrogen. The resulting hydrogen is stored in the gas network and later converted into power again. This ‘clean gas’ can be stored for a very long time —weeks or even months. However, studies have shown it to be expensive and inefficient so far. (McKinsey and Company)

2. We need better battery technology

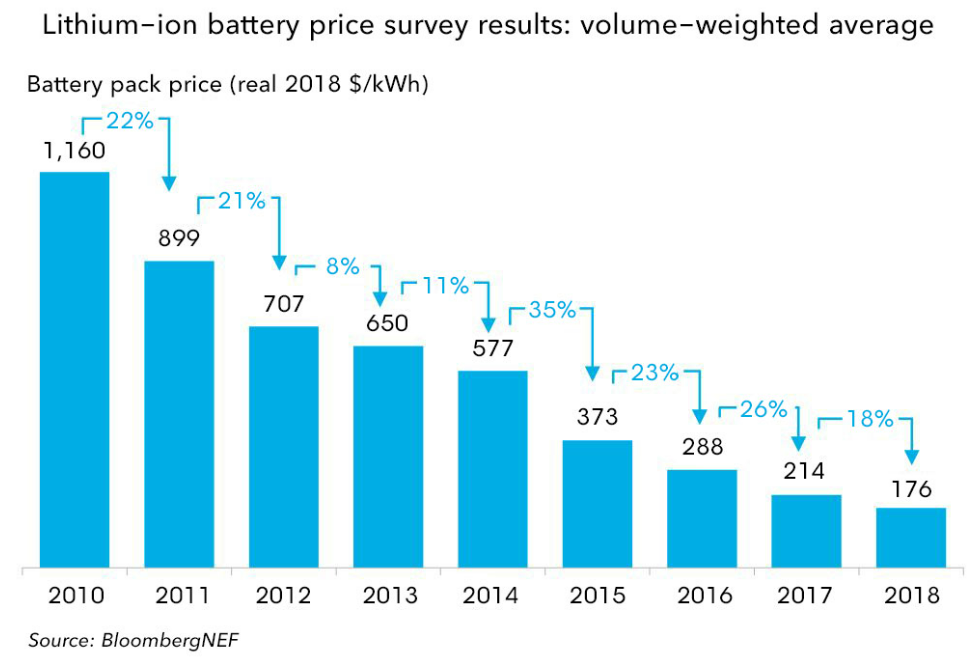

Secondly, we need lighter batteries. So, innovation plays a critical role. In the last 10 years the cost of battery packs has declined by 95%, and this trend will likely continue. Manufacturers with the best batteries will dominate the car industry. Currently, weight reduction is the main focus of development. However, things like fast-charging, battery life, fire risk, and manufacturing cost are also important.

In fact, by 2025, better battery density will let a 40-tonne truck drive 400 km on a single charge. With more powerful batteries on the horizon, the average range might rise to around 800 km.

3. We need faster charging technology

Thirdly, we need much faster charging technology. Speeds have been vastly improved with new technology. For example, it once took 2.5 hours to charge a heavy-duty electric truck. With faster chargers, full charging is now possible over 45 minutes for every 4.5 hours of driving (equal to a standard driving break). By the end of the 2022, new megawatt charging stations will make charging even faster.

Also, internet access to services will make charging stations more reliable. For example, operators may be able to control stations remotely, or optimise their energy use, or conduct routine maintenance.

Tests are underway to assess various charging solutions along transport routes. An e-HDV smart charging station may require a combination of stationary buffer batteries, on-site renewable electricity generation, and digitised charging points.

To achieve all these changes, cooperation between private and public sectors is essential. Consequently, we need international policies and agreements which support low carbon transport.

Policies for Carbon Neutral Transport

In order to build the massive infrastructure that will provide electricity supply to charging stations it is necessary to create national and international standards ensuring consistency and reliability. It is also important to direct investment to other forms of low carbon transport, like biofuels and hydrogen.

Infrastructure

Electric Heavy Duty Vehicles (HDV’s) will require:

- A much larger and denser network of charging points and re‐fuelling stations. Heavy duty transport vehicles will also require dedicated charging points.

- Sufficient truck (and bus) electric charging points. Hydrogen (LH2/CH2) and gas (CNG/LNG) refuelling stations will need to be built by 2025 at the latest.

- Standardisation of technical settings to ensure consistency and access. For example, ready access to high‐power charging for commercial vehicles (HPCCV) on long distance travel. A variety of charging points will also be needed for other kinds of vehicle.

- Private charging points should be available, as well as public or semi‐public charging points.

- Financial incentives to encourage investment by large fleet owners. Subsidies will encourage transport operators to invest ahead of time. (European Automobile Manufacturers Association)

Policy Initiatives

The World Economic Forum’s new Decarbonizing Road Freight Initiative will bring together stakeholders from across the e-trucking ecosystem to accelerate the transition to zero-emission heavy-duty vehicles in Europe.

This sort of policy initiative is vital to accelerate investment and build industry level knowledge.

“The initiative will work to co-create actionable roadmaps, de-risking pilots and financing models for demand and supply-side actors of the eco-system. In addition, the initiative aims to contribute to the policy work of renowned think tanks and established cross-industry initiatives such as Transport & Environment, RAP, ICCT and ECTA.”

World Economic Forum

Yet, when it comes to freight, HDV’s are not the whole story. What about low carbon transport in the aviation industry?

Is Low Carbon Air Transport Possible?

The argument for electric commercial aircraft has re-emerged with concerns around the impact of air travel on the environment.

Nevertheless, how will electric aircraft actually reduce the environmental footprint of aviation? What would this kind of aircraft look like, and how will its operation compare to a conventional jet? We must ask which technologies are really needed, and which of them are already in place. (CEAS Aeronautical Journal)

For an aircraft to be commercially viable, the efficiency of its operation is paramount. This means getting the most power with the least amount of waste.

Efficiency in Aviation

In aviation, efficiency means getting the highest amount of thrust. Thrust lets the aircraft to create the right amount of lift to counter the effects of gravity and drag. Not surprisingly, one of the most important factors in designing commercial aircraft is the weight to lift ratio. So, with electrical aircraft, the weight of the battery cell in relation to the power it produces is of major concern. It directly affects how many passengers and freight the aircraft is be able to carry.

The choice of jet engines or propellers and their arrangement on the craft is another design choice that affects efficiency. Electric planes so far mostly involve propellers. Interestingly, these allow for vertical take-off and landing. (McNair Research Journal)

The benefits of electric planes

- They are quieter

- The electric motor requires less maintenance than a jet engine

- The air is a better environment for batteries for optimal operation

- Jet engines are only 26% efficient, whilst electric motors are 90% efficient (Electric Future)

Other power alternatives for Low Carbon Aircraft?

The all-electric aircraft is just one possibility for a more eco-friendly fleet of aircraft. Other power alternatives include:

- Conventional designs that use synthetic fuels, efuels or biofuels

- Hybrid solutions with a wide variety of hybridisation (of power and energy)

- Gas fuel powered aircraft using pressurised or liquid hydrogen, liquefied petroleum gas (LPG), or liquefied natural gas(LNG)

- Fuel cell powered planes. For example, hydrogen can be a combustible fuel. However, it can also be a source of power for battery-like fuel cells.

- Other battery or electric energy-storing technologies such as liquid batteries and superconductors. (CEAS Aeronautical Journal)

Fossil Free Aviation

Today, jet engines are one of the most powerful engines on earth but they are incredibly harmful to the environment.

Manufacturers are working on solving design problems at a pace. Currently leading the pack is Norway, a country that has pledged to make all domestic planes electric by 2040.

“Technological solutions exist. Sustainable fuels, electrified aircraft and hydrogen will, together with efficiency in airspace and technologies that lower emissions from the fleet, enable fossil free aviation.”

– Avinor report (2020)

Many airline companies around the world are researching a range of battery and hydrogen solutions. Unfortunately, both of these still pose problems for commercial operations. Batteries are heavy and hydrogen takes up a lot of space.

Nevertheless, the world is working toward cleaner, quieter planes. These could one day replace all the aircraft currently in use today. Once again, international co-operation and incentives will play an important part in making this happen.

Let’s not be complacent

In conclusion, the commercial freight vehicle sector is transforming. Battery-electric power is a new entrant, vying with hydrogen, biomethane and other biofuels.

Replacing fossil fuels is essential if we are to avoid the worst of the climate crisis. Change is possible. By leveraging the available scientific research in our value chains, we can achieve greater wealth, productivity, and a flourishing economy and society.

At THRIVE, we call this the state of ‘thrivability’. The Thrive Project is a not-for-profit, for-impact research, education and advocacy organisation. Want to find out how THRIVE can help your business? Contact The THRIVE Project for more information, and sign up to our newsletter for the latest updates.