Textiles are everywhere. From the clothes that you wear to the seats that line your car and the carpet that covers your floors. But what happens to unwanted textiles?

Australians buy about 27 kg of new clothing every year. In comparison, the amount of clothing that is disposed of in Australia averages to 23 kg per person (Inside Waste, 2020). However, less than 1% of unwanted textiles are recycled in Australia (Sustainability Victoria, 2018), with about 88% that have been sent straight to landfills between the years 2009-2011 (ABS, 2013).

On top of these problems lies the issue of the fashion industry. The fast-fashion industry mass-produces clothing under very poor working conditions. Thousands of employees are underpaid and exposed to toxic conditions when dyeing and making fibres. For instance, check out the cost and work that goes into denim here.

It’s quite clear that the sustainability of the textile industry has not been developed. The recent hype around “sustainable textiles” and “sustainable clothing” has been a top hit, as consumers are becoming more aware of the issues in fashion and wish to be more ethical about these damaging practices.

Common textile materials that you might have seen hanging on shelves of any shop include cotton, leather/suede, polyester, nylon, viscose, and rayon. Thus, the increase in “sustainable fibres” have added bamboo, linen, and recycled polyester to the list.

This recent demand for fashion circularity has also called for more sustainable textiles. A wave of more eco-friendly fibres is in the market, from fast-fashion brands, such as Zara and H&M, to luxury designers, such as Burberry and Gucci. These brands have began advertising their “conscious” materials and incorporating a new range of clothing that is targeted to these demands. The real question is, which is the best out of these “sustainable” textiles?

COTTON

Cotton is well known for its breathability and is one of the most commonly used plants for clothing fibres. The plant matures after around 180 days (Cotton Australia, n.d.), where it is harvested and baled for weaving.

Depending on the rain that is received in each season, cotton requires about 6–7 ML per hectare of water (Crop and Pasture Science 2013). Furthermore, pesticides are harmful to the environment, where they dissipate through waterways and natural forests, intoxicating the natural habitat of birds, fish, and plants. Some farmers use these pesticides to reduce the loss of yield during the growing season. The good news is, a 2019 report by Cotton Australia, saw a 18.2% drop in pesticide usage.

Moreover, organic cotton has seen a recent increase in the market, which is grown without chemicals, such as pesticides and fertilisers. Farms that are certified (such as ACO, OEKO-Tex) grow organic cotton. However, this certification can take more than three years to earn.

BAMBOO

Bamboo is a fast-growing plant, where within three months, the stalks can reach up to 20 meters in height. The plant is harvested when it is four years or older. This surpasses the beginning of its mature age, at least in the case of textiles.

The plant does not require the use of fertilizer or pesticides, making it eco-friendly to grow. However, most of the bamboo that is utilised for textiles is harvested from China. For some, this raises questions on ethical working conditions for those harvesting the plant and the environmental impact upon clearing.

In addition, bamboo does not require much water to grow. In fact, bamboo does not prefer receiving that much water. This makes it a better option to use over cotton, with added benefit of not requiring the use of pesticides.

According to Bamboo Textiles, the processing of the bamboo fibre uses two main chemicals – both of which can lead to severe impacts on the people and environment if not limited. The chemicals are needed to dissolve the bamboo’s tough plant cells and to extract the fibre itself.

LINEN

The flax plant matures after around 90-120 days, which is much faster than cotton and bamboo (Duke, 1983). One flax plant can grow up to 70 cm in height and 20 cm wide, where it requires 150-200 mm of water over the growing season. In perspective, many reports quote the European Confederation of Linen and Hemp stating a linen shirt would only use 6.4 L, which is much less than a cotton shirt that requires 2.7 GL.

Fertilizers and pesticides are also kept to a minimum (Duke, 1983), however, that still does not mean that it is not used. Fertilisers can lead to the increased growth of algae in waterways, which can affect the health of the ecosystem. You might be then wondering, why are we not using more linen? It’s because the work involved in creating the fabric is labour-intensive, resulting in higher prices for businesses and customers to buy. In addition, the dyeing process uses harmful chemicals. This destroys the environment as a result, according to Good on You.

RECYCLED POLYESTER

We’ve all seen pictures of wild animals with swallowed bottle caps or marine life that have died due to our plastic rubbish. The growth of man-made material in our lives is hurting our natural environment, hence we are calling for action to reduce our plastic waste. Small plastic pellets are made from post-consumer waste, which is then melted and woven into fabrics. This creates the recycled polyester or rPET fabric we see in clothes.

With recycling being one of the main solutions to managing waste, just how much is it solving our problem?

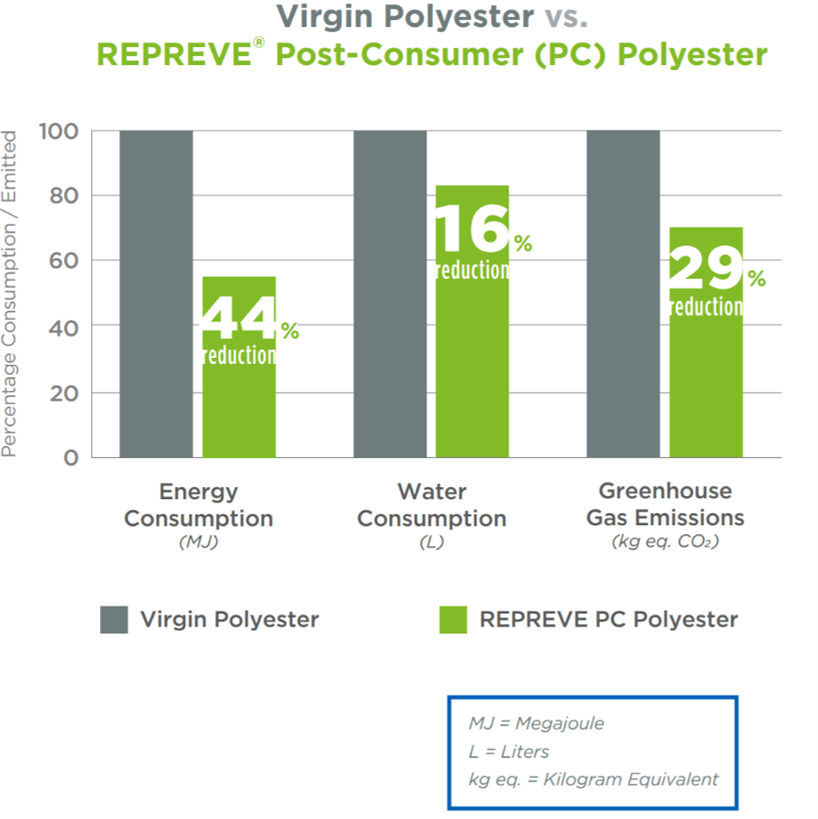

Looking into one manufacturing company of rPET, Unifi has released its 2020 Sustainability report, where they show that producing rPET used 44% less energy, 16% less water, and released 29% fewer greenhouse gases. Moreover, Unifi claims to have collected over 20 billion plastic bottles out of the landfill in the past year (Unifi, 2020). Sounds good, right?

Unfortunately, recycling plastic has its limits – the quality reduces over time, and thus, the fibres do too. As a result, more microplastics are released back into the environment. In addition, we know that plastic takes tens to hundreds of years to break down.

WRAP UP

So what is the best material to wear? What is the worst? For now, there is no clear method to rapidly disintegrate plastic. However, natural fibres take months to break down, while it takes decades in the case of synthetic fibres. If you consider the “best” fabric to be the one with less damage to the environment and less water, then linen would be the best option, followed by cotton. However, the worst fabric would depend on your perspective. If ethics are your concern, then bamboo might not be for you. Similarly, recycled polyester would not be the best in the case of the environment. Overall, natural fibres trump synthetics in terms of their degradability.

We must realise that we all have the power to drive change. As consumers, we have the power to make a change. Firstly, by choosing our purchases wisely and recognizing the hard labour that has been put into each garment. Next, buy secondhand pieces, where you can visit local op shops, such as Vinnies and the Salvation Army, or online websites that sell pre-loved clothing. Lastly, if you have to buy brand-new, purchase from ethical brands. As your last resort, shop timeless pieces, as wearing clothes for longer makes all the difference.

For more information, visit the THRIVE Project for those who want to make a positive contribution towards a prosperous and sustainable future.

References

Australian Bureau of Statistics. 2013. CHAPTER 4: Waste. [online] Available at: https://www.abs.gov.au/ausstats/[email protected]/Products/4655.0.55.002~2013~Main+Features~Chapter+4+Waste?OpenDocument

Bamboo Textiles. How Is Bamboo Textile Fibre Made?. [online] Available at: https://www.bambootextiles.com.au/bamboo-information/how-is-bamboo-textile-fibre-made/

Cotton Australia. n.d. Cotton Australia | How Is Cotton Grown?. [online] Available at: https://cottonaustralia.com.au/how-is-cotton-grown

Crop and Pasture Science 64(12) 1033-1048 https://doi.org/10.1071/CP13315

Submitted: 6 September 2013 Accepted: 5 December 2013 Published: 18 December 2013.

Duke, J. A. 1983. Handbook of Energy Crops. unpublished.

Newman, Clare. 2020. Material Guide: How Sustainable is Linen?. [online] Available at: https://goodonyou.eco/how-sustainable-is-linen/.

Inside Waste, 2020. Tackling Textile Waste. [online] Available at: https://www.insidewaste.com.au/index.php/2020/05/19/tackling-textile-waste/#:~:text=Australians%20send%20an%20average%2023kgs,Bureau%20of%20Statistics%20(ABS).

Krebet, I., 2020. Examining Textile Waste From Brands And Charities – ACTA. [online] ACTA. Available at: https://acta.global/news/used-textile-waste-from-brands-and-charities/.

Palamutcu S. 2017. Sustainable Textile Technologies. In: Muthu S. (eds) Textiles and Clothing Sustainability. Textile Science and Clothing Technology. Springer, Singapore.

https://www.ethical.org.au/3.4.2/get-informed/issues/cotton-pesticides/

Sustainability Victoria. (2018) Statewide Waste snd Resource Recovery Infrastructure Plan Melbourne: Sustainability Victoria.